Every electrician completes electrical test and inspections, normally in domestic dwellings, as part of the bread and butter of our trade. However, every once in a while a more out-of-the-ordinary opportunity comes up… as it did for us at Matt Payne Electrical at the end of 2018.

Salisbury Cathedral

Being presented with the opportunity to carry out the electrical test and inspection of Salisbury Cathedral was one we grabbed with both hands. The job came with its challenges and its joys, some of which we’d like to share with you in this blog.

But first, what is an electrical test and inspection? Put simply, this involves visually inspecting the electrical distribution equipment and the accessible cables and electrical accessories (ie sockets, lights, switches etc) on each circuit. A comprehensive checklist of inspections are graded C1-C3 on the inspection schedule (depending on the severity of the electrical safety) or as a PASS if all is well. A sampling percentage of the electrical accessories on each circuit are tested for earth continuity and insulation resistance etc.The test results are recorded on a schedule of test results.

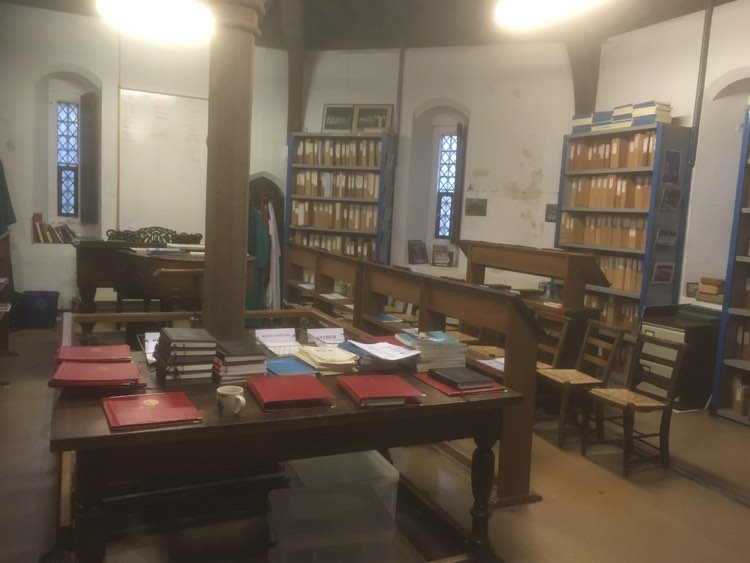

Choir practice room

Joys

Working in such a magnificent building was a real treat. More than 600,000 tourists visit Salisbury Cathedral every year to marvel at its architecture and explore its historical and spiritual roots. We were working in the building for a few weeks and got to explore areas in the roof and up spiral stair cases that Joe Public were not allowed access to. Some of the old fashioned keys we were given to open up ancient oak doors, looked like something out of a medieval film set.

I remember one morning I was in the building before anyone else. It was quite unusual have no-one else around. I stood in the centre of the buildings footprint and gazed around in a 360 degrees sweep, soaking in the tranquil atmosphere before visitors poured in the doors.

Being in the Cathedral festive season meant we heard the choir practices early in the morning before the tourists arrived. While testing the sockets in the choir practice room we gained an insight into some of the preparation undertaken for these festive services.

Challenges

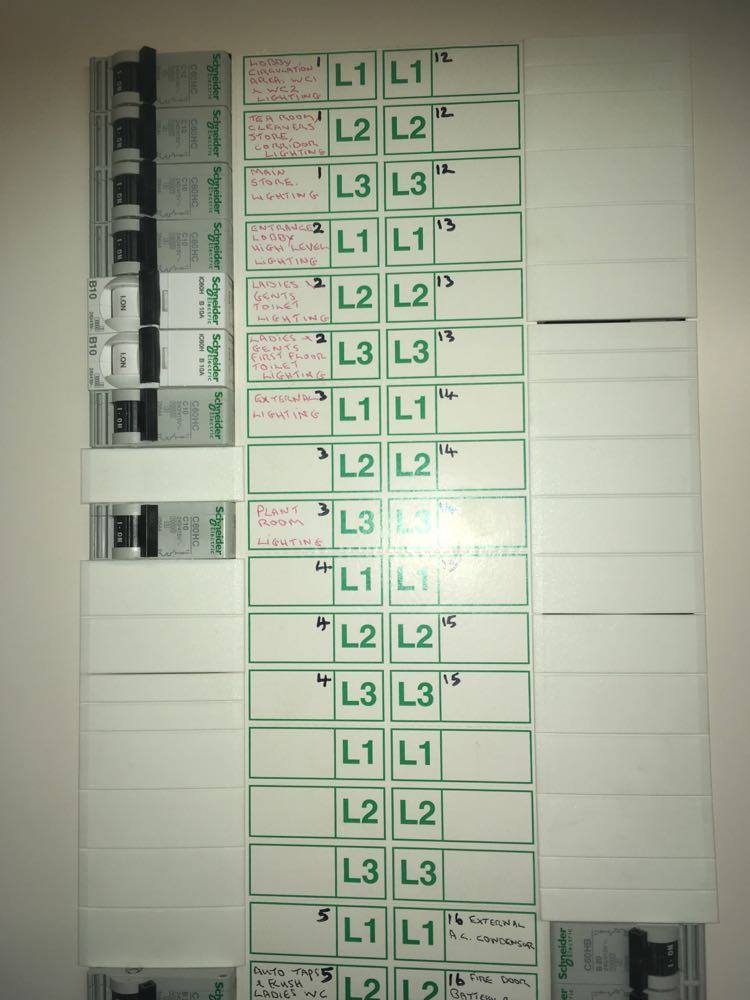

Being such a large electrical installation with so many distribution boards and circuits it can be quite difficult actually finding which sockets, lights etc are actually connected to which circuits. Then throw into the mix the fact that some circuits can’t be turned off, to minimise disruption to the public and the day-to-day workings of the Cathedral. However, with some ingenuity and persistence we identified circuits and could legitimately test some circuits ‘live’ (always maintaining our health and safety).

Some planning ahead was needed to access some of the areas of the Cathedral, especially where negotiating spiral staircases was concerned and narrow walkways to access the higher levels of the building.

Some parts of the building simply are not accessible for electrical testing, however, a sampling percentage is acceptable to identify if the circuit is ‘acceptable for continued use’. You may be wondering if the red light at the top of the spire was tested? Alas, this was out of our remit and quite out of reach – literally!

Modern meets ancient

Distribution board in Little Paradise

The Cathedral is over 700 years old, but new additions have been made such as the café and a section housing the modern toilets and addition rooms affectionately known as ‘little paradise’. This also housed the boiler room and one of the more recent electrical distribution boards.

Salisbury Cathedral boiler room

Engineering feats

Having started my working life as an engineer it was fascinating to see the mechanical and electrical workings of aspects of the Cathedral. The pipe organ has its own ‘blowing chamber’ – a room with motor driven bellows to blow air through the pipes of the organ which produce the familiar organ sounds. The motors start up when the organist hits the ‘start’ button by his keyboard.

Earlier this year, during the huge organ restoration project, we had the task of running in a new socket circuit for the different sections of the organ electronics. These sockets powered up the organ when the contactor on the blowers was started up. We got to see other parts of the building not seen by the public on that job – included a cable tunnel which runs under the choir section! Thank goodness I have an apprentice!

As our electrical test and inspection ventured to the working buildings surrounding the Cathedral we worked alongside the stone masons in their workshops. It was quite amazing to see the detailed drawings of each stone on the Cathedral numbered and some identified as needing restoration work or replacement. I never realised that as they carve and chip at the stone block they work under a suction hose to suck away the harmful stone dust – quite a noisy environment to continually work in.

Oh course the most staggering engineering feat at the Cathedral is the building itself. We got the opportunity to see it close up and from many different angles and to enjoy the views across the water meadows from its turrets. Looking at the size and weight of each stone and the considering the lack of mechanical and electrical aids back in the day of its construction, does make you marvel at the commitment and dedication of the builders.

Even in more modern times, to fit the electrical installation into a building of this proportion is quite a feat. Here’s some facts relating to the electrical installation:

Electrical facts

Types of cable used: steel wired armoured cable, MICC fire proof cable, more modern FP200 fire proof cable, PVC twin and earth, flex

Number of distribution boards: 45

Number of circuits: 529

Since this job we have been back to the Cathedral and other properties in Cathedral Close to carry out electrical installations and electrical test and inspections, and have been very happy to do so. So many thanks to the Clerk of Works (Gary Price) for using our services.

If you need an electrical test and inspection certificate, whatever the shape, size or age of your property, please contact us on 01722 449114.

No comments yet.